JOINT BASE – The Naval Air Warfare Center Aircraft Division stationed in Lakehurst is supplying face shields to a hospital ship that’s been serving a hotspot for COVID-19.

The division is delivering 500 plastic face shields to the USNS Comfort which is stationed off New York City, according to base officials. The hospital ship was brought in to help NYC hospitals with the overflow of patients.

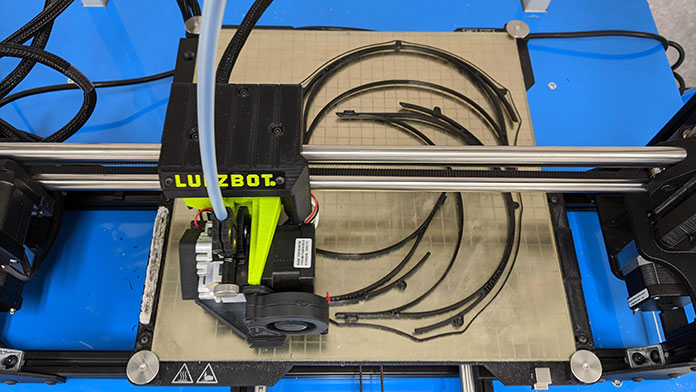

The shields are being made with a 3-D printer, which literally creates physical objects one level at a time.

“The battle against COVID-19 is a team effort, and I can’t thank our team enough for their hard work and dedication to getting the USNS Comfort the equipment they need for this fight,” said Kathleen Donnelly, NAWCAD Lakehurst executive director. “We are in this together, and will keep striving for solutions in providing PPE [Personal Protective Equipment] to our local community.”

The Lakehurst facility was usually metal-based, according to Kyle Cobb, NAWCAD Lakehurst AM technology lead. They had to expand on this with new machines to print PPE.

They acquired 12 LulzBot TAZ Workhorses and a C02 laser cutter to enable a higher rate production of face shield material, Cobb said.

The NAWCAD Lakehurst advanced manufacturing/prototype engineering team worked with the Naval Air Systems Command (NAVAIR) AM team to ensure that all shields produced are high quality and meet requirements.

Meanwhile, NAWCAD Lakehurst is also working on designs for ventilators and respirators, and producing PPE via traditional manufacturing methods.

“It has been an extremely rewarding experience to leverage our industrial capabilities to respond to this global health crisis,” Cobb said. “I personally have many family members and friends who are military personnel, healthcare workers and first responders who are on the front line so I realize how important this effort is.”

One issue they had to overcome is their own social distancing in the lab when making the PPE. To do this, the Digital Engineering Division is setting up a remote monitoring system so team members can monitor the printing process via webcam from the safety of their homes.

This might solve more than one problem, Cobb said. Being able to monitor construction remotely might lead to the team being able to work on long metal builds and CT scans when creating naval aviation parts.

The Department of Defense, Federal Emergency Management Agency (FEMA) and the Food and Drug Administration alongside the medical community are working to coordinate the production (via 3D printing and standard manufacturing) of medical supplies in response to the COVID-19 pandemic.